DEOCOMMERCE LTD WASTEWATER TREATMENT

For hotels and restourants

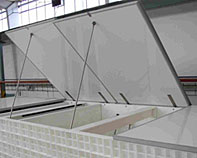

Packing wastewater Treatment Plants

Biological treatment

Biological treatment is based on biological reactor BC. This reactor incorporates all stages of the biological treatment, including the separation of the activated biological sludge. The separating settling tank is separating the excessive sludge. The internal structures split tanks into particular compartments enabling all functions of the biological treatment, i.e. biodegradation, nitrification, and denitrification. Internal circulation assures the function of the activated sludge circulation from the separation section.

The group wastewater treatment installations (type BC) are with the service range of 25 to 500 equivalent residents.

The described arrangement of the compact biological reactor enables complex treatment of the municipal wastewater. High efficiency of the separation assures the function of the plant with high-activated sludge concentration. (4 - 6 kg SS / m3).

DESCRIPTION OF TREATMENT PROCESS

Inlet

The wastewater flows to the denitrification section of the plant (DN).

Biological treatment

Mechanically pre-treated water (basket screen) flows into the denitrification zone of the reactor. The organic waste is used as a source of carbon for denitrification processes. Water from the denitrification zone in the activation/nitrification section where separation structures are fixed. Here the excessive sludge is separated from the purified water in the final settling tank. The clean water continues in the recipient. Airlift pumps assure the re-circulation between separation and denitrification zones.

All the sections of the reactor are connected in the closed circuit where activated sludge circulates. In the individual sections there are conditions with different concentration of the dissolved oxygen – a zone with stable oxygen deficit for denitrification and zones with variable oxygen deficit for secondary denitrification processes. The internal circulation serves in the same time for equable distribution of the separated suspension returned from the separation zone.

Sludge management

Production of the excess biological sludge is minimized using the low-loaded activation process. This way the complete simultaneous aerobic stabilization of the sludge is assured. (Sludge age is approximately 30 days.)

GUARANTEED EFFLUENT PARAMETERS

| Parameter | Average Performance | |

| BOD55 | (mg/l) | 20 – 25 |

| COD | (mg/l) | 60 – 100 |

| SS | (mg/l) | 25 – 30 |

| N-N4 | (mg/l) | 2 – 5 |

| P total | (mg/l) | 5 - 8 |

Operation personnel

One operator for 2-3 hour weekly will operate the plant, excepting periodical maintenance of the equipment. The operation will be described in details in the Operation Manual supplied with the plant.

LEGEND

DN – Denitrification; ACT – Activation; DОS – Clarifier (separation); NK – Basket screen; DM – Blower; 1.0 – Inlet; 1.1 – Connect DN-АСТ; 1.2 - INLET TO DOS; 1.3 - Recirculation; 1.4 – Outlet; 1.5 – Air system

| Type | Num. of persons |

Load BSK5 kg/day |

Capacity m3/day |

Power input kW |

Total weight kg |

Мeazur- ment м |

Num of tanks ks |

Inlet level m |

Outlet level m |

| BC 35 | 35 | 2.1 | 7 | 0.55 | 850 | 4x2.16x2.08 | 1 | 1.8 | 1.3 |

| BC 50 | 50 | 3 | 10 | 0.55 | 1 000 | 4x2.16x2.58 | 1 | 2.3 | 1.7 |

| BC 75 | 75 | 4.5 | 15 | 1.1 | 1 200 | 5x2.16x2.58 | 1 | 2.3 | 1.7 |

| BC 100 | 100 | 6 | 20 | 1.5 | 1 500 | 6.5x2.16x2.58 | 1 | 2.3 | 1.7 |

| BC 150 | 150 | 9 | 30 | 1.5 | 2 400 | 5x2.16x2.58 | 2 | 2.3 | 1.7 |

| BC 200 | 200 | 12 | 40 | 3 | 3 000 | 6.5x2.13x2.58 | 2 | 2.3 | 1.7 |

| BC 250 | 250 | 15 | 50 | 3 | 3 800 | 5.5x2.16x2.58 | 3 | 2.3 | 1.7 |

| BC 300 | 300 | 18 | 60 | 3 | 4 000 | 6x2.16x2.58 | 3 | 2.3 | 1.7 |

| BC 400 | 400 | 24 | 80 | 3 | 5 400 | 6x2.13x2.58 | 4 | 2.3 | 1.7 |

| BC 500 | 500 | 30 | 100 | 4.4 | 8 000 | 6x2.16x2.58 | 6 | 2.3 | 1.7 |

TIME OF DELIVERY - 3-5 weeks after the date of order

WARRANTY

24 months after the date of commissioning, excepting the components where their manufacturer guarantees shorter period.

2016 © Deocommerce Limited. All rights reserved